Grizzly G0619 CNC Conversion

Contents

Introduction

Summary:

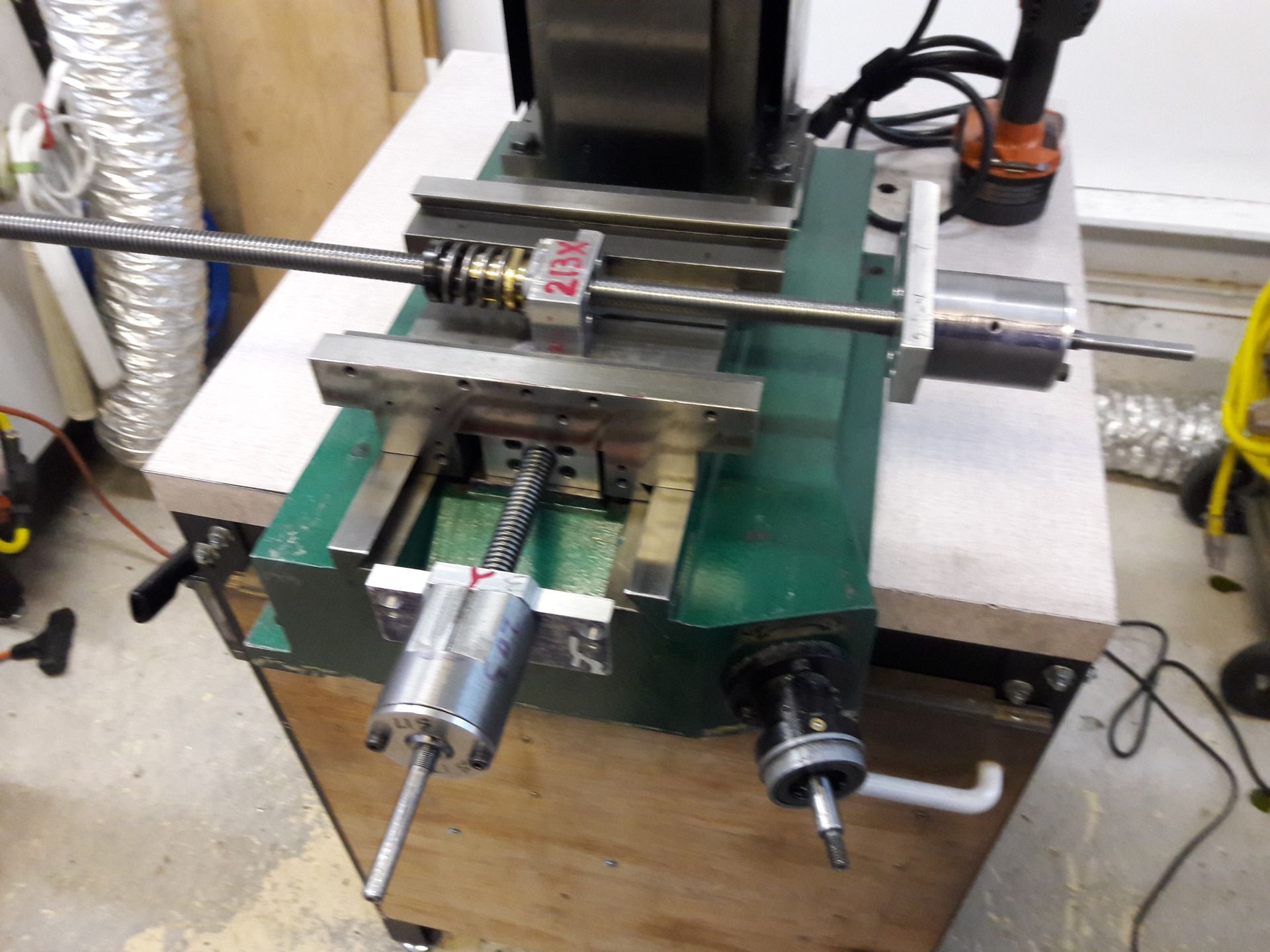

This a very brief write up of a multi-year project to build a fully functional CNC Milling machine using a Grizzly G0619 as a basis.

Why:

From the very beginning the objective of the project was to use LinuxCNC as a control system. During the construction LinuxCNC and the associated Linux Real-Time kernel went thru may changes which made the project even more complex.

Building blocks:

The 3 main sections are as follow:

- Machine modifications to allow for the installation of the new hardware

- Define and configure the new control using a closed loop servo system built around LinuxCNC.

- Setup up the software and tune the control loop - PID Tuning for the machine to function with resonable response and accuracy.

Background

Why do THIS

Coming soon

How to do THIS

Buy a Grizzly G0619 and design your own conversion with servo motors, encoders, anti-backlash nuts and then build all the parts on the same machine that you are about to convert.

There are lots of Youtube videos that talk about similar conversions, those are all done by folks who bought a kit and just mounted the parts and made a video. Most use stepper motors, that not the same thing as this. We have a fully feedback closed loop control system just like the "real" CNC machines.

A Working CNC

A demo of the semi-finished machine

feel free to play at 2X speed.

More to do

Need to add tool height setter, spindle speed control for adaptive machining, make a new spindle for BT-30 quick tool changes, etc.

Control and Electronics

Motors

DC servo motors

Encoders

US Digital high res encoders

Motion Control

MESA 5i20 board

Software

LinuxCNC all the way